Conveyors for chips, swarf and scrap metal handling

Hinged Steel Belt Conveyors (MBC), Scraper Conveyors (DFC), Magnetic Conveyors (MC)

Our chip conveyors save your costs

These types of chip conveyors are mainly used for removing chips from machining steel, stainless steel, aluminum, cast iron and other metals or plastics. We manufacture chip conveyors for CNC lathes, CNC milling machines, machining centers and other CNC or standard machine tools. We will manufacture a conveyor for any type of machining device or for transport of the required components, scraps, forgings or waste for you.

How do I simply choose a correct conveyor type?

Choose the conveyor type based on the type of chip and transported material, or send us your demand directly.

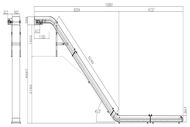

Even long or tall conveyors are not a problem for us

Why chip and scrap conveyors brand name BROXTEC? Our 12 main advantages:

- All our hinged steel belt chip conveyors, scraper and magnetic conveyors are always watertight.

- The tracks and bottom of scraper chip conveyors are always offered / made of highly wear-resistant material.

- For highly demanding operations, we offer tracks and bottoms from highly wear-resistant material (HARDOX); we also use this material for the hinged steel belt conveyors.

- Furthermore, for extreme operations, we offer thermal treated axles of belts, main axle and other specialties improving the working life of the conveyors.

- The warranty is extended to 24 months for selected types, or pursuant to agreement.

- We are not strictly limited by a modular system, we can adjust the design of a conveyor exactly as you need.

- Our conveyor design, with pitch 1.5" and 2.5", allows changing a scraper conveyor to a hinged steel belt conveyor by a simple replacement of the scraper chain to metal hinge belt and the other way around. This is very convenient for companies which change the machined material from cast iron to steel and then back.

- The cross-section of the conveyor remains the same along the entire length. This limits jamming the conveyor. The height of the load section is from 118 mm – very important for machines with limited space.

- The width of a chip conveyor with pitch 1.5" and 2.5" is always a multiple of 1" (25.4 mm). That means that we can offer much larger width series, wider always only by 25.4 mm compared to other manufacturers.

- We offer option to change the speed of the belt by simply replacing the sprockets, or using a switch board with frequency changer.

- The hinged steel belts with pitch 1.5" and 2.5" consist of individual robust parts, they are not welded together. This grossly improves the sturdiness of the belt and, at the same time, it is easy to disassembly the belt and, eventually, to replace a damaged part.

- We offer several design options of the drive and protection against overload, preventing from pulling the chips under the belt, etc.